|

Blasting Halls

More than 70 % of all blasting, de-scaling and derusting work is carried out stationarily in halls, cabins or special plants. The advantage: the abrasive can be used much more often. In principle, the abrasive has been reused in all semiautomatically or fully automatically working blasting halls and blasting chambers. Before using again the abrasive has to be cleaned thouroughly.

|

|

|

|

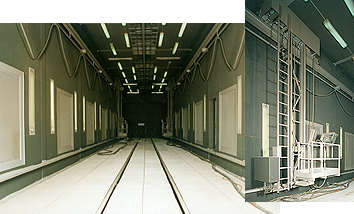

Combined blasting

and coating hall

for ship sections

|

|

Abrasive - return systems (semiautomatic)

Return "pit", collecting hopper

Partial return. The abrasive is pushed to the conveying system.

Transverse conveyance with storage trough

Partial return by worm or vibration conveyor trough.

|

|

|

|

Blasting hall

with machines

in container design |

|

Abrasive - return systems (fully automatic)

Scraper system

Sheet metal paddle with rubber tape draws the abrasive over the floor to the bucket elevator. During the back motion the paddles fold down and run over the abrasive. The system is simply structured and convinces because of its low building depth.

Vibration conveyance system

Feeding of the troughs is realised via the metal sheet funnels, the troughs are oscillating into the direction of the bottom. These vibrations cause the abrasive to "jump" forward. Because transport takes place in the air the system requires less maintenance and the wear is low, too.

Reprocessing

All systems are based on the unitised construction principle. They consist of the bucket elevator, the abrasive cleaner with precipitation of coarse particles and air separation as well as a storage facility. Dimensioning is adapted to the return system and the abrasive circulation. Optionally with magnetic separator to separate the abrasive from steel particles.

Ventilation and dedusting

It is very important to catch efficiently the dust generated during the blasting process and to separate it at an efficient filter plant. Vibration facilities or pneumatic dedusting processes are used to clean the filters. All air pipes are built in a stable manner, and they are protected by labyrinths or baffle plates. In winter, it is possible to feed the cleaned air again into the blasting hall to save heating costs.

Blasting halls

We offer dust resistant, all-steel constructions consisting of individual segments which have been screwed up or bolted. Walls, ceilings and doors are insulated. Stable folding sliding doors or electrically driven rolling doors with protective blinds are used as doors.

|

|

|

|

Wagon - Blasting hall

with

movable platforms

for lifting people

|

|

Laying out

Walls and ceilings are laid out with highly abrasion-proof and silencing special rubber plates.

Lighting

Our special lamps are dust resistant and resistant to abrasives. They have been designed especially for the use in blasting halls.

Transport systems

We delivery the necessary transport systems to charge the abrasive halls like rail transport vehicles, roller tables, telpher lines or platforms for lifting people.

Blasting technology

Our well proved Taifun pressure blasting pot is used in the standard form or in form of a double chamber. We deliver ready to use including hoses, nozzles, protective equipment and emergency shut-down devices according to german law BVG D 26 (see KIESS Total Product Range).

Cleaning with compressed air

Complete compressed air units with compressor, air dryer, compressed-air storage device and oil-water separating system.

|

|

|

|

Processing unit consisting of

bucket elevator, cleaner, magnetic separator,

silo and blasting pot

|

|

|

|